Mechatronics Students Vie for SICK TiM $10K Challenge

This story was updated October 2, 2020

CPTC mechatronics team shines in national contest

The wheels started turning last fall. Clover Park Technical College mechatronics students Jesse Moore, Todd Ritchie and Austin Tomasu had to come up with an industry-changing product using technology commonly found in self-driving cars. That early brainstorming developed into an application that ultimately fulfilled a major Mechatronics program requirement. It also landed them in a national competition with some of the country’s top engineering colleges and universities, and gave them a shot at a $10,000 prize.

The CPTC team is among an elite group participating in the second annual SICK TiM $10K Challenge. The competition tasks students to solve a problem, create a solution and develop a new system using a Light Detection and Ranging, or LiDAR, sensor. LiDAR technology uses laser pulses to build a 3D model of the environment around an autonomous vehicle. In a nutshell, LiDAR acts as the eye of the car, ensuring it drives safely.

Problem, meet solution

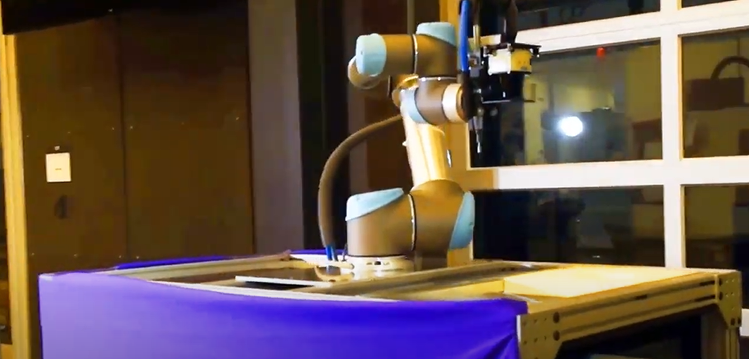

Typical camera-based machine vision doesn’t detect certain edges in low or changing light conditions. With guidance from program instructor and advisor Jason Sawatzki, Moore, Ritchie and Tomasu figured out how to solve those limitations using the LiDAR sensor and a robotic arm. After hours of research, testing, programming and data analysis in and outside of the classroom, they had their solution – the Robo-Replicator.

“The CPTC mechatronics team took it outside the bounds and used the sensor as a 3D scanner,” Sawatzki said. “They created a computer model of an existing part that can be copied by carving out material using the same robotic arm.” They achieved that using their combined mechatronics skills—from software development, to electrical and communications interfaces, to the mechanical design of the part at the end of the robotic arm that holds the sensor and a rotary tool.

For the competition, the team had to complete their prototype and produce an entertaining video that would demonstrate their technical achievement and highlight the system’s appeal to potential customers. And, as a result of unforeseen circumstances, they needed to get it done much more quickly than originally planned.

“We realized as early as January there might be a shutdown due to COVID-19,” Moore said. “We modified our timeline to finish the project and produce our final video.” They completed on-site filming the week before CPTC closed to students, and wrapped final voice-overs and editing remotely before submitting their video and a paper ahead of the contest deadline.

Time for a dance party

Focused on spotlighting their technical achievements through a marketing lens, the mechatronics team created a video that begins like a bygone, black and white industrial film, then moves into the future with the disco-themed unveiling of the Robo-Replicator, complete with electro-techno music and strobe lights to demonstrate the system’s ability to function in varying light conditions. The original video concept called for a big dance party with CPTC students from across campus, but social distancing guidelines necessitated the film be made with a minimal film crew and cast. Regardless, the team made it work.

“Our ability to get this project finished with a pandemic looming entirely came down to excellent communication and teamwork across the entire team, as well as exceptional faculty support,” Moore said.

“We are very proud of their project and video performance,” Sawatzki said. "The team came together under extremely challenging circumstances to produce an outstanding technical achievement."

The project was part of the trio’s Applied Mechanics class, and a culminating element of the CPTC Mechatronics program. With an emphasis on design and production of automated equipment, the multidisciplinary field combines mechanical, electrical, telecommunications, control and computer engineering. Students gain work-ready practical skills to prepare for a wide span of careers in such fields as robotics, agricultural automation, programmable logic controller (PLC) programming, control systems, smart infrastructure or industrial automation.

Creating this new technology is a big deal, and so is inclusion in the TiM $10K Challenge. Beyond having their project showcased in a national competition, Moore, Ritchie and Tomasu will be able to show their finished project to potential employers.

On Friday, October 2, 2020, the Clover Park team received this exciting update:

Dear Clover Park Team,

I have some exciting news to share with you!

In recognition of your hard work and impressive video that your team submitted last March, and the packaging application of the project, SICK and PMMI are happy to award your team a cash prize.

Congratulations!

Join us in congratulating team members, Austin Tomasu, Jesse Moore, and Todd Ritchie on winning this prize and for their ambitious and technically challenging project. We are very proud of this team! The Sick TiM $10K Challenge, a national competition that included top engineering universities from around the country.

The CPTC mechatronics team video is available on YouTube. (Keep an eye out for “Professor” Ritchie doing The Worm.) Winners of the competition will be announced the end of May.

Share This Story

Ready to learn more? Visit the Mechatronics program page on the Clover Park Technical College website.