The future of manufacturing: CPTC gets ready for Industry 4.0

By Jean Borst

A new era in manufacturing is here – and so are new jobs and career pathways. As rapid advances drive demand for skilled workers, Clover Park Technical College (CPTC) is laser-focused on ensuring students are ready to keep pace with evolving technology.

Building tomorrow’s workforce

Since the 1760s, there’s been a remarkable progression in the way machines change our lives. Steam was the big deal during the first Industrial Revolution; electricity drove the second; and machines and automation shaped Industry 3.0.

Today, Industry 4.0 integrates technologies like cloud computing, artificial intelligence, machine learning, and big data and analytics to make the manufacturing process more productive, efficient and cost-effective.

With the recent co-location of additional programs in CPTC’s John W. Walstrum Center for Advanced Manufacturing, the college has advanced its efforts to ensure students have the skills and training they need to succeed in the Industry 4.0 era.

The center, which opened in 2019, was built to replicate best industrial practices to provide students a fully immersive experience. The space initially housed CPTC’s Advanced Composites Manufacturing, Manufacturing Engineering Technologies, Mechatronics and Nondestructive Testing programs. Last year, Computer Programming, Network Operations & Systems Security (NOSS) and Cybersecurity programs were relocated to the building.

“Industry 4.0 is about the applications coming together,” CPTC Dean of Instruction Dr. Claire Korschinowski said. “By co-locating the programs in one space, we have created an environment of continuous learning and adaptability as emerging technologies evolve.”

With CPTC’s advanced manufacturing disciplines together in one physical space, work will continue to make sure they’re operating together on a virtual level.

“Interconnectivity is the end goal,” Korschinowski said. “That will be our primary focus in 2024.”

Funding boost will elevate programs

CPTC recently received two significant grants that will support and enhance Industry 4.0 training for students pursuing careers in advanced manufacturing:

- $280,000 Aerospace High Demand 1000 Full-Time Equivalent Student (FTES) funding. This funding source was created to address the aerospace skills gap in Washington state by ramping up training in high-demand aerospace programs in community and technical colleges. Of the $280,000 awarded to CPTC, $80,000 will support the college’s BAS in Mechatronics Engineering Technologies and Automation program, and $200,000 will help grow the Manufacturing Engineering Technologies (MET)

- $1.2 million Career Launch grant for equipment funding. Career Launch programs provide students with real-life work experience related to their academic studies. On the heels of earning a Career Launch endorsement in June 2023, CPTC’s MET program received funding to purchase and install equipment. The grant will ensure the college has the most up to date equipment that aligns with industry standards to ensure MET students have the knowledge and skills they need to be prepared for high-demand careers in advanced manufacturing.

You can learn more about the MET Career Launch endorsement and funding here.

A people-powered revolution

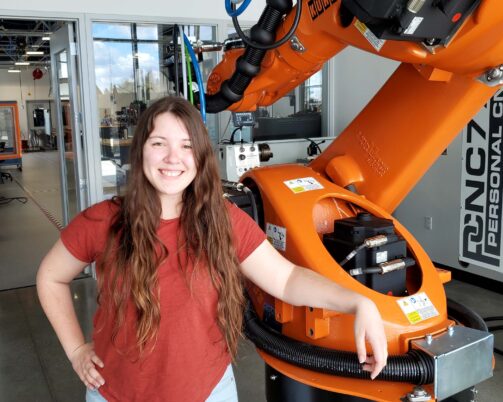

Industry 4.0 aims to automate many manufacturing tasks and make processes smarter and faster than ever before. But that doesn’t mean robots and machines will replace people.

“It’s a common misconception that automation eliminates jobs, but it actually creates new jobs and opportunities,” Korschinowski said. “We need humans to operate and maintain this technology. The goal is to reskill and upskill people to put them in these new roles, not take them out of the workforce. Our School of Advanced Manufacturing is doing just that.”